Offering the same superior protection against damaging micro abrasive dust as the turbo II is our latest generation precleaner, the turbo III. Made up of high strength glass-reinforced polymer, the turbo III Precleaner carries the same high efficiency, low restriction reputation of the turbo II only lighter and easier to install.

Unique design prevents micro-abrasives from entering the machine’s engine and is proven by OEM’s in the most demanding applications and environments, ensuring years of trouble-free service.

Same efficient “top-down” flow design as the industry leader, turbo II, drawing dirty air through the protective screen at the top of the unit and ejecting it out.

turbo® III is available in four sizes covering a CFM range from 15 to 1100 CFM.

Available models include Model 15, Model 50, Model 200, The NEW Model 390, and Model 500 and multiple inlet diameters for convenient installation (refer to chart below).

The turbo® III precleaner prolongs the life of your engines by significantly reducing engine wear. It’s the precleaner of choice for equipment operators in the dustiest, dirtiest environments.

turbo® III is critical to maintain effective engine breathing. When ventilation is clean and efficient, the engine performs at maximum efficiency and power.

turbo® III features durable glass-filled polymer construction, which means it’s stronger while being lighter and smaller and is UV resistant and corrosion-proof.

turbo® III clamps on in mere minutes and requires no complicated installation or extensive tools.

turbo® III’s durable metal construction comes backed by a 2-year warranty. It’s the precleaner chosen by OEMs and equipment owners and operators worldwide for it’s efficiency and durability.

Designed specifically for equipment used in landfill, agricultural, and other similar harsh environments, the turbo HD packs all of the same features as turbo II, plus an added layer of extra protection.

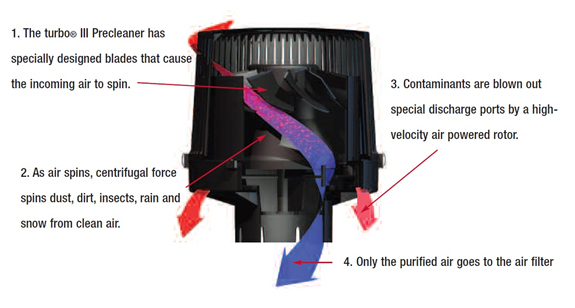

turbo® III Precleaner is made out of 33% glass-reinforced polymer (nylon 6), and is designed with the same “TOP DOWN” airflow as the turbo® II. The “Top Down” design draws dirty air through the protective screen at the top of the unit. The patented “stacked vane” forces the incoming air to spin and cause separation of dust and dirt from the air by centrifugal force. The dust and debris then spins down the wall of the main chamber and into the blower chamber where the high velocity spinner forces the dirt to the discharge ports at the base of the unit. As the velocity of the primary air stream increases, it ejects out additional dirt and debris providing the cleanest possible air to the filter element. This design offers exceptional balance between added restriction and efficiency. The new patented “stacked vane” configuration has improved the precleaner efficiency by preventing the blow-through effect common in other polymer units.

Competitors typically use “REVERSE AXIAL” designs. This means that the air is drawn in through the base of the unit and then must make a “U” turn which adds restriction and reduces the power of the engine. Additional restriction to the engine will cause the need for more frequent engine filter replacements.

turbo® Precleaners are tested to industry SAE J726 and ISO 5011 standards.

turbo® III is currently manufactured in four sizes and covers a CFM range from 15 to 1100 CFM.

Additionally, turbo® III is also available as an “inline” model (Flex-N-Line™) for mounting the Precleaner under the hood and allowing the engine to still draw in fresh, clean air in high dust environments.

| turbo® III Precleaner | Inlet Size Base | Outside Diameter | Height | Weight | |||||||

| Product Description | Model Number | CFM Range | Inches | mm | Inches | mm | Inches | mm | LBS | kg | Separation Efficiency Curve |

| Model 15-2″ | 21-1320000 | 15-85 | 2″ | 50.8mm | 5.27″ | 133.86mm | 5.13” | 279mm | .5lbs | 0.23kg | Click Here |

| Model 15-2″ Bullnose | 21-1320001 | 15-85 | 2″ | 50.8mm | 5.27″ | 133.86mm | 5.13” | 279mm | .5lbs | .23kg | Click Here |

| Model 50-3″ | 21-1330000 | 50-250 | 3″ | 76.2mm | 7.5″ | 190.5mm | 8″ | 203.2mm | 1.5lbs | 0.68kg | Click Here |

| Model 50-4″ | 21-1330001 | 50-250 | 4″ | 101.6mm | 7.5″ | 190.5mm | 8″ | 203.2mm | 1.5lbs | .68kg | Click Here |

| Model 200-4.5″ | 21-1345000 | 200-500 | 4.5″ | 114.3mm | 9.34″ | 237.24mm | 11.6″ | 294.64mm | 4.4lbs | 1.99kg | Click Here |

| Model 200-5″ | 21-1350000 | 200-500 | 5″ | 127mm | 9.34″ | 237.24mm | 11.6″ | 294.64mm | 4.4lbs | 1.99kg | Click Here |

| NEW Model 390-5″ | 21-1450000 | 300-700 | 5″ | 127mm | 12.37” | 323.34mm | 11.49” | 291.85mm | 6lbs | 2.72kg | Click Here |

| NEW Model 390-6″ | 21-1460000 | 300-700 | 6″ | 152.4mm | 12.37” | 323.34mm | 11.49” | 291.85mm | 6lbs | 2.72kg | Click Here |

| NEW Model 390-7″ | 21-1470000 | 300-700 | 7″ | 177.8mm | 12.37” | 323.34mm | 11.49” | 291.85mm | 6lbs | 2.72kg | Click Here |

| Model 500-6″ | 21-1360000 | 500-1100 | 6″ | 152.4mm | 13.8″ | 350.2mm | 14.1″ | 358.14mm | 7.5lbs | 3.40kg | Click Here |

| Model 500-7″ | 21-1370000 | 500-1100 | 7″ | 177.8mm | 13.8″ | 350.2mm | 14.1″ | 358.14mm | 7.5lbs | 3.40kg | Click Here |

| Model 500-8″ | 21-1380000 | 500-1100 | 8″ | 203.2mm | 13.8″ | 350.2mm | 14.1″ | 358.14mm | 7.5lbs | 3.40kg | Click Here |