turbo® II performs it’s job in the toughest environments day in and day out. The unique design is all about preventing micro-abrasive dust from entering the machine’s engine creating cleaner air to prolong the engine life. turbo® II is the industry standard precleaner by which all precleaners are judged.

From its durable metal construction to its high efficiency and low restriction across the entire range, turbo® II is chosen worldwide by equipment operators for installation on loaders, graders, crushers, haulers, mixers, and mining machines. Anywhere a high level of protection is needed and where dust is an issue, the turbo® II is a must.

Unique design prevents micro-abrasives from entering the machine’s engine.

The only precleaner that leverages “top down” air flow, drawing dirty air through the protective screen at the top of the unit and ejecting it out.

turbo® II is available in four sizes covering a CFM range from 100 to 1100 CFM.

Available models include Model 24, Model 35, Model 46, and Model 68 (refer to chart below).

You have a job to worry about, you shouldn’t need to bother with charging or maintaining parts. turbo® II is self-cleaning and never needs external power or charging.

The turbo® II precleaner prolongs the life of your engines by significantly reducing engine wear. It’s the precleaner of choice for equipment operators in the dustiest, dirtiest environments.

turbo® II is critical to maintain effective engine breathing. When ventilation is clean and efficient, the engine performs at maximum efficiency and power.

turbo® II protects your engine from particulate as small as one micron. Maximum protection means little to no down time. Anywhere a high level of protection is needed and where dust is an issue, the turbo® II is a must.

turbo® II clamps on in mere minutes and requires no complicated installation or extensive tools.

turbo® II is backed by a lifetime warranty on the high-powered, highly efficient ejection spinner. It’s the precleaner chosen by OEMs and equipment owners and operators worldwide for it’s efficiency and durability.

Designed specifically for equipment used in landfill, agricultural, and other similar harsh environments, the turbo HD packs all of the same features as turbo II, plus an added layer of extra protection.

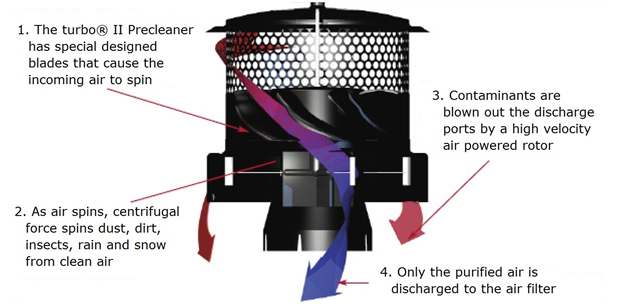

The turbo® II is the only metal precleaner that offers a “Top Down” air flow by drawing dirty air through the protective screen at the top of the unit. turbo® II Precleaners have aerodynamically designed overlapped vanes that force the incoming air to spin and causing separation of dust and dirt from the air by centrifugal force. The dust and debris then spins down the wall of the main chamber and into the blower chamber where the high velocity spinner forces the dirt to the discharge ports at the base of the unit. As the velocity of the primary air stream increases, it ejects out additional dirt and debris providing the cleanest possible air to the filter element. This design offers exceptional balance between added restriction and efficiency.

Competitors typically use “REVERSE AXIAL” designs. This means that the air is drawn in through the base of the unit and then must make a “U” turn which adds restriction and reduces the power of the engine. Additional restriction to the engine will cause the need for more frequent engine filter replacements.

turbo® Precleaners are tested to industry SAE J726 and ISO 5011 standards.

turbo® II is currently manufactured in four sizes and covers a CFM range from 100 to 1100 CFM. Additionally turbo® II offers a similar model made out of high strength glass-reinforced polymer that is lighter in weight and easier to install, the turbo® III.

| turbo® II Precleaner | Inlet Size Base | Outside Diameter | Height | Weight | |||||||

| Product Description | Model Number | CFM Range | Inches | mm | Inches | mm | Inches | mm | LBS | kg | Separation Efficiency Curve |

| Model 24 – 3″ | 21-1024000 | 100-250 | 3″ | 76mm | 8″ | 203mm | 11″ | 279mm | 5lbs | 2.3kg | Click Here |

| Model 24 – 4″ | 21-1024015 | 100-250 | 4″ | 102mm | 8″ | 203mm | 11″ | 279mm | 5lbs | 2.3kg | Click Here |

| Model 35 | 21-1035000 | 250-350 | 4.5″ | 114mm | 9.25″ | 235mm | 12.25″ | 311mm | 6.5lbs | 2.9kg | Click Here |

| Model 46 – 4 1/2″ | 21-1046000 | 350-700 | 4.5″ | 114mm | 12.25″ | 311mm | 15.5″ | 394mm | 11lbs | 4.9kg | Click Here |

| Model 46 – 5″ | 21-1046001 | 350-700 | 5″ | 127mm | 12.25″ | 311mm | 15.5″ | 394mm | 11lbs | 4.9kg | Click Here |

| Model 46 – 6″ | 21-1046002 | 350-700 | 6″ | 152mm | 12.25″ | 311mm | 15.5″ | 394mm | 11lbs | 4.9kg | Click Here |

| Model 46 – 7″ | 21-1046003 | 350-700 | 7″ | 178mm | 12.25″ | 311mm | 15.5″ | 394mm | 11lbs | 4.9kg | Click Here |

| Model 68 – 6″ | 21-1068001 | 700-1100 | 6″ | 152mm | 14.5″ | 368mm | 17.5″ | 444mm | 16lbs | 7.3kg | Click Here |

| Model 68 – 7″ | 21-1068002 | 700-1100 | 7″ | 178mm | 14.5″ | 368mm | 17.5″ | 444mm | 16lbs | 7.3kg | Click Here |

| Model 68 – 8″ | 21-1068003 | 700-1100 | 8″ | 20mm | 14.5″ | 368mm | 17.5″ | 444mm | 16lbs | 7.3kg | Click Here |